LEDs generate far less heat than the incandescent technology they replace, so they are a significantly safer option. However, the small amount of heat they do generate must be efficiently removed from the LED chip, otherwise the anticipated life of the product may be reduced.

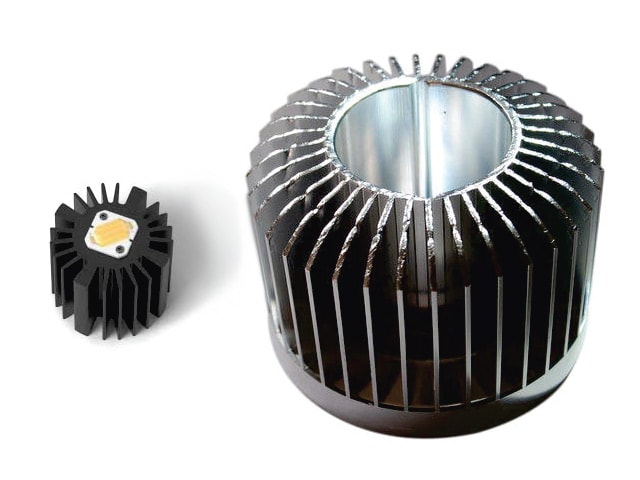

The method presently and most commonly used to dissipate heat is known as a heat sink. This is usually a piece of extruded aluminium used for its characteristic ability to allow rapid flow of thermal energy, thus allowing the LED chip to have its heat wicked away for safe long-term operation. The aluminium is often seen produced with fins and other interesting shapes.

These odd shapes often increase surface area to allow effective heat dissipation. As LED technology improves through increased efficacy, we will see these heat sinks reduce in size and perhaps disappear from view. For now, they are still evident in some form in most LED products.

If we consider how hot some roof spaces can be in summer, even a well designed LED luminaire with a reasonable size heat sink may reach temperatures too hot to touch.

Depending on the design, this heat sink temperature can be considered normal on a hot day in a roof space, given that many modern LED chips are designed to operate at 120 degrees or more without adversely affecting the anticipated lifetime of the product.